In the realm of paper decoration manufacturing, where creativity dances on the delicate fibers of paper, every aspect matters. From the intricacy of design to the durability of the final product, each step in the manufacturing process contributes to the quality and appeal of the decorations. Among these critical steps, selecting the right supplier for raw materials stands as a cornerstone. In this blog, we delve into the importance of choosing the right supplier for raw materials in paper decoration manufacturing, explore the intricacies of product technology, and highlight essential paper decoration equipment.

Understanding Paper Decoration Manufacturing:

Before delving into the significance of selecting the right supplier, it's imperative to understand the nuances of paper decoration manufacturing. Unlike other forms of manufacturing, where materials might be rigid or malleable, paper decorations demand a unique blend of sturdiness, flexibility, and aesthetic appeal.

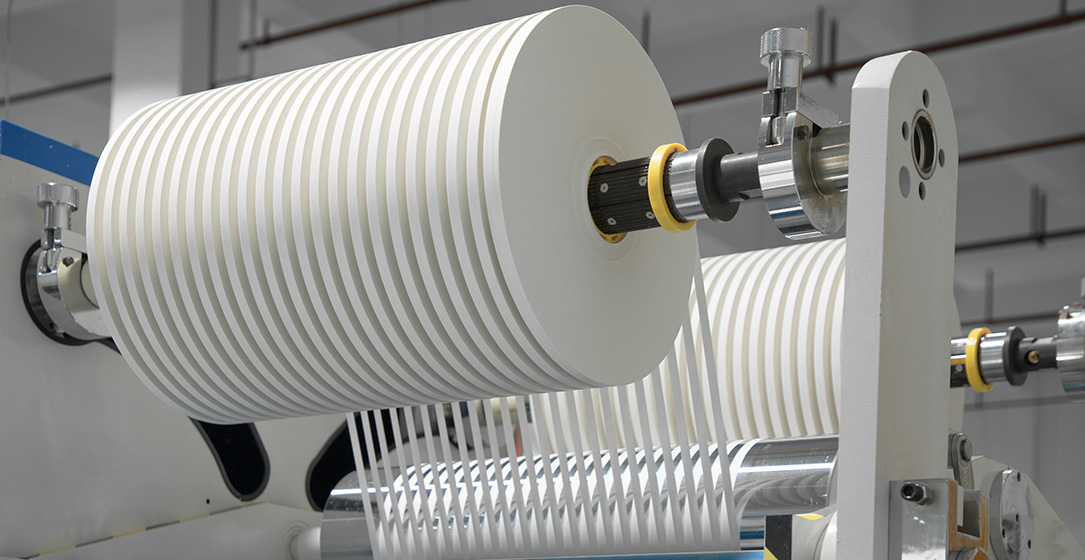

The process typically begins with the selection of appropriate raw materials—paper being the primary ingredient. Depending on the desired outcome, various types of paper such as crepe paper, tissue paper, or even recycled paper might be utilized. These papers differ in texture, thickness, and color, offering manufacturers a broad palette to work with.

Once the raw materials are procured, the manufacturing process involves cutting, shaping, and assembling the paper into intricate designs. Advanced product technology plays a pivotal role here, facilitating precision and efficiency in production while ensuring the final product meets the desired quality standards.

The Significance of Choosing the Right Paper supplier:

In the realm of paper decoration manufacturing, the quality of raw materials directly impacts the quality of the final product. Therefore, choosing the right supplier becomes paramount. Here's why:

Quality Assurance: A reliable supplier ensures consistent quality in raw materials, which is essential for maintaining the integrity of the final product. Whether it's the color vibrancy of the paper or its tensile strength, consistent quality is non-negotiable.

Innovative Solutions: The right supplier doesn't just provide materials but also offers innovative solutions that cater to the evolving needs of the industry. Whether it's introducing eco-friendly alternatives or experimenting with new textures, a forward-thinking supplier can add immense value to the manufacturing process.

Timely Delivery: In the fast-paced world of manufacturing, delays can be detrimental. A dependable supplier understands the importance of timely delivery, ensuring that manufacturers have a steady supply of raw materials to meet production deadlines.

Cost Efficiency: While quality is paramount, cost efficiency cannot be overlooked. The right supplier offers competitive pricing without compromising on quality, thereby helping manufacturers optimize their production costs.

Collaborative Partnership: Beyond mere transactions, the relationship between a manufacturer and a supplier should be characterized by collaboration and mutual support. A reliable supplier acts as a strategic partner, offering guidance and support to enhance the manufacturing process.

Exploring Product Technology:

In the realm of paper decoration manufacturing, product technology plays a pivotal role in enhancing efficiency and precision. From automated cutting machines to digital printing technologies, advancements in product technology have revolutionized the manufacturing process.

Automated Cutting Machines: Traditional methods of cutting paper can be time-consuming and prone to errors. Automated cutting machines streamline this process, allowing for precise cuts and shapes, thereby improving efficiency and minimizing wastage.

Digital Printing: Digital printing technologies have opened up a world of possibilities in paper decoration manufacturing. From intricate patterns to vibrant colors, digital printing enables manufacturers to achieve unparalleled levels of detail and customization.

Embossing and Die-Cutting: Embossing and die-cutting techniques add depth and dimension to paper decorations, transforming flat sheets of paper into intricate works of art. Advanced machinery allows for precise embossing and die-cutting, ensuring consistency across large production runs.

Quality Control Systems: Product technology isn't just about production; it also encompasses quality control systems that monitor and maintain the quality of the final product. From color calibration systems to defect detection algorithms, these systems help ensure that every paper decoration meets the desired quality standards.

Essential Paper Decoration Equipment:

While product technology plays a significant role, it's essential not to overlook the importance of traditional paper decoration equipment. From basic tools to specialized machinery, the right equipment is indispensable in bringing creative visions to life.

Cutting Tools: Basic cutting tools such as scissors and craft knives are essential for shaping and trimming paper. For larger-scale production, rotary cutters and guillotine cutters offer efficiency and precision.

Creasing and Folding Machines: Creasing and folding machines are used to create crisp folds and creases in paper, essential for intricate designs such as origami and accordion folds.

Gluing and Adhesive Equipment: Whether it's glue sticks for small-scale projects or industrial-grade adhesive applicators for large-scale production, reliable gluing and adhesive equipment are indispensable in paper decoration manufacturing.

Embossing and Die-Cutting Machines: Specialized embossing and die-cutting machines allow for intricate designs and patterns to be stamped onto paper, adding texture and visual interest to the final product.

Drying Racks and Presses: Once assembled, paper decorations often require drying or pressing to ensure they maintain their shape and integrity. Drying racks and presses facilitate this process, allowing for efficient drying and pressing of multiple pieces simultaneously.

In the world of paper decoration manufacturing, every detail matters. From the selection of raw materials to the implementation of advanced product technology, each aspect of the manufacturing process contributes to the quality and appeal of the final product. By choosing the right supplier for raw materials, embracing innovative product technology, and utilizing essential paper decoration equipment, manufacturers can unlock new levels of creativity and efficiency, ensuring that every paper decoration is a masterpiece in its own right.