In the realm of home décor, weddings, and celebrations, paper decorations have emerged as versatile and customizable elements that add charm and personality to any setting. Gone are the days of generic, one-size-fits-all decorations; today, consumers crave uniqueness and personalization in every aspect of their lives. This growing demand has spurred the rise of customized production in paper decorations, where advanced manufacturing techniques and innovative Product technology converge to create bespoke pieces that enchant and captivate. In this blog post, we'll explore the intricate world of customized Paper decoration manufacturing , delve into the nuances of Product technology, and unveil the essential equipment that powers this creative industry.

The Evolution of Paper decoration manufacturing

The art of Paper decoration manufacturing has undergone a remarkable transformation in recent years, evolving from traditional mass production to customized craftsmanship. This shift has been driven by changing consumer preferences and advancements in manufacturing technology, which have empowered manufacturers to offer a diverse range of personalized options.

In the realm of Paper decoration manufacturing , Customization begins at the design stage. Talented designers leverage digital tools and software to create intricate patterns, motifs, and themes tailored to specific occasions, themes, or individual preferences. From whimsical florals to geometric abstractions, the possibilities are endless, limited only by the bounds of imagination.

Once the designs are finalized, the manufacturing process kicks into high gear. Advanced printing technologies, such as digital and offset printing, enable precise reproduction of intricate details and vibrant colors on various types of paper. From lightweight tissue paper to sturdy cardstock, manufacturers carefully select materials that complement the design aesthetic and ensure durability.

Product technology: Bridging Creativity and Innovation

At the heart of customized paper decoration production lies a tapestry of Product technology that seamlessly integrates creativity with innovation. From design software to cutting-edge printing techniques, each technological advancement plays a crucial role in bringing personalized creations to life.

CAD (Computer-Aided Design) software serves as the cornerstone of the design process, allowing designers to translate their creative visions into digital reality with unparalleled precision. These sophisticated software tools offer a myriad of features, including 3D modeling, pattern generation, and simulation, empowering designers to experiment and iterate until they achieve perfection.

In the realm of Printing technology, digital printing has emerged as a game-changer, revolutionizing the production process with its flexibility and efficiency. Unlike traditional printing methods, digital printing eliminates the need for costly setup fees and allows for on-demand printing of small batch orders. This enables manufacturers to offer personalized designs with quick turnaround times, catering to the evolving needs of consumers in today's fast-paced world.

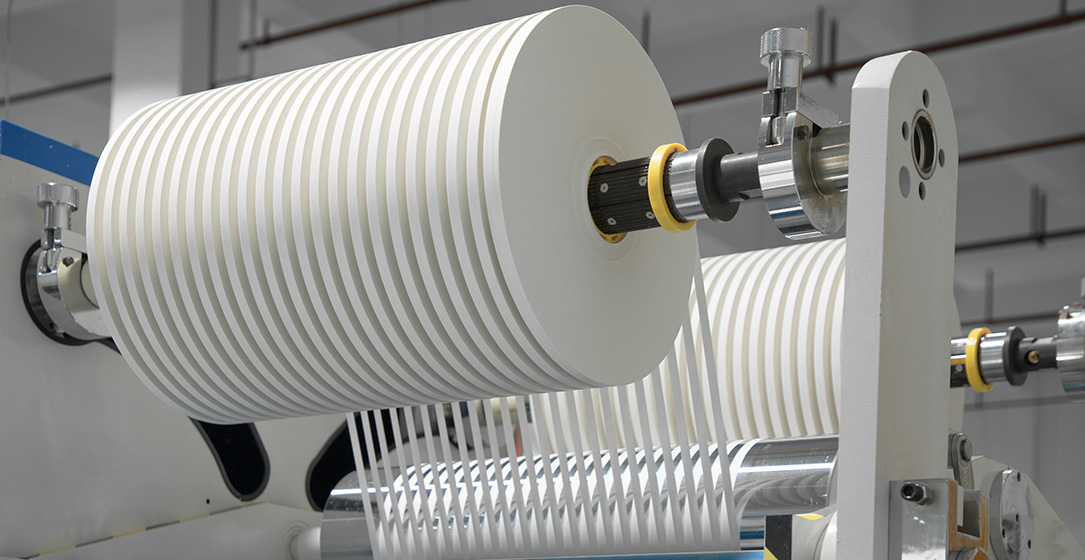

Paper decoration equipment: Powering Creativity

Behind every exquisitely crafted paper decoration lies a suite of specialized equipment that powers the creative process. From printing presses to cutting machines, each piece of equipment plays a crucial role in transforming raw materials into works of art.

Offset printing presses are commonly used for high-volume production of paper decorations, utilizing metal plates to transfer ink onto paper with unparalleled precision. These presses ensure consistent color reproduction and sharp image quality, essential for capturing the intricate details of customized designs.

Cutting-edge CNC (Computer Numerical Control) cutting machines automate the cutting process, enabling manufacturers to cut out intricate shapes and patterns with remarkable accuracy. Equipped with high-speed rotary blades or laser cutters, these machines ensure consistency and efficiency in production, regardless of the complexity of the design.

Folding and scoring machines streamline the assembly process, creating crisp folds and creases in paper decorations with precision and ease. These machines are equipped with adjustable settings to accommodate a wide range of paper weights and thicknesses, ensuring uniformity across the entire production run.

In conclusion, the customized production of paper decorations represents the perfect marriage of creativity and innovation. Through advanced manufacturing techniques, Product technology, and specialized equipment, manufacturers can offer personalized creations that delight and inspire consumers. Whether it's a whimsical centerpiece for a wedding or a festive garland for a birthday party, customized paper decorations add a touch of magic to any occasion, making every moment truly unforgettable.