Introduction:

Paper decorations have become a ubiquitous feature in modern interior design, adding charm, elegance, and personality to various spaces. Behind the beauty of these decorations lies a meticulous production process flow that combines craftsmanship, technology, and creativity. In this blog, we delve into the intricacies of the Paper decoration production process flow, from design conception to final assembly, highlighting the role of product technology and paper decoration equipment along the way.

Design Conception and Development:

The paper decoration production process begins with design conception and development. This stage involves brainstorming ideas, sketching concepts, and creating digital mockups of the desired decorations. Designers use specialized software to manipulate shapes, colors, and patterns, bringing their creative vision to life.

Product Technology Integration:

Product technology plays a crucial role in the design conception and development stage of the paper decoration production process. Advanced design software allows designers to experiment with various design elements, visualize concepts in 3D, and simulate how decorations will look in different environments.

Moreover, product technology facilitates collaboration between designers, manufacturers, and clients, enabling seamless communication and feedback exchange throughout the design process. By integrating product technology into the design conception and development stage, manufacturers can streamline workflows, reduce design iterations, and accelerate time-to-market for new paper decorations.

Material Sourcing and Preparation:

Once the design concept is finalized, the next step in the paper decoration production process flow is Material sourcing and preparation. Manufacturers must carefully select high-quality paper stock that meets the desired specifications in terms of color, weight, texture, and finish.

Product Technology: Product technology plays a crucial role in material sourcing and preparation, enabling manufacturers to streamline procurement processes, track inventory levels, and optimize material usage. Inventory management software allows manufacturers to monitor stock levels in real-time, identify trends in material consumption, and forecast future demand.

Moreover, advancements in paper cutting technology, such as automated cutting machines, enable manufacturers to cut large quantities of paper with precision and efficiency. By integrating product technology into material sourcing and preparation, manufacturers can ensure a steady supply of high-quality materials while minimizing waste and reducing production costs.

Printing and Decoration:

Once the materials are sourced and prepared, the next stage in the paper decoration production process flow is printing and decoration. This stage involves transferring the design onto the paper stock using various Printing techniques, such as digital printing, offset printing, or screen printing.

Product Technology Integration: Product technology plays a crucial role in the printing and decoration stage of the paper decoration production process. Digital printing technology, for example, offers high-resolution printing capabilities, allowing manufacturers to reproduce intricate designs with stunning clarity and detail.

Moreover, advancements in inkjet technology enable manufacturers to achieve vibrant colors, smooth gradients, and crisp details, enhancing the visual appeal of paper decorations. By integrating product technology into printing and decoration processes, manufacturers can achieve higher levels of efficiency, quality, and customization in paper decoration production.

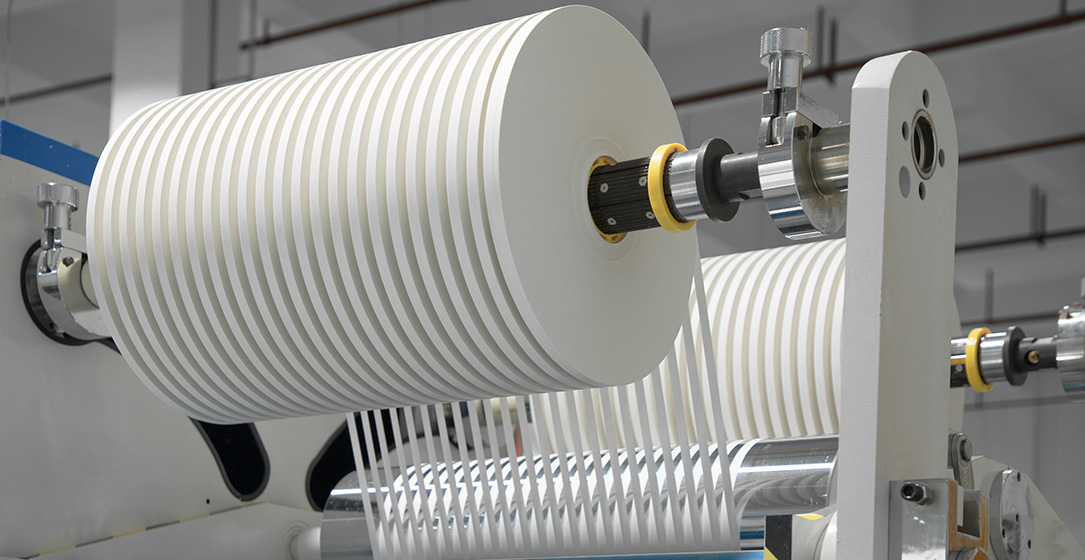

Cutting and Shaping:

After printing and decoration, the next stage in the paper decoration production process flow is cutting and shaping. This stage involves cutting the printed paper into various shapes and sizes using specialized cutting equipment, such as die-cutting machines or laser cutters.

Product Technology Integration: Product technology plays a crucial role in cutting and shaping processes, enabling manufacturers to achieve precise cuts and intricate shapes with minimal waste. Die-cutting machines, for example, use custom-made dies to cut paper into precise shapes and designs, offering unparalleled accuracy and consistency.

Moreover, advancements in laser cutting technology enable manufacturers to cut paper with precision and speed, allowing for complex designs and intricate details. By integrating product technology into cutting and shaping processes, manufacturers can optimize material usage, minimize waste, and reduce production costs.

Assembly and Finishing:

The final stage in the paper decoration production process flow is assembly and finishing. This stage involves assembling the various paper components into the final decoration, adding embellishments, such as ribbons or beads, and applying finishing touches, such as varnish or laminate, to enhance durability and appearance.

Product Technology Integration: Product technology plays a crucial role in assembly and finishing processes, enabling manufacturers to streamline workflows, improve efficiency, and enhance quality. Automated assembly lines, for example, use robotic arms and conveyor systems to automate repetitive assembly tasks, reducing labor costs and cycle times.

Moreover, advancements in finishing technology, such as UV coating or embossing, enable manufacturers to add visual and tactile elements to paper decorations, enhancing their aesthetic appeal and perceived value. By integrating product technology into assembly and finishing processes, manufacturers can achieve higher levels of consistency, quality, and customer satisfaction.

Conclusion:

In conclusion, the paper decoration production process flow is a complex and intricate journey that combines craftsmanship, technology, and creativity. From design conception to final assembly, each stage of the production process plays a crucial role in creating beautiful and distinctive paper decorations.

Product technology, including design software, Cutting equipment, and assembly lines, plays a crucial role in streamlining workflows, enhancing efficiency, and improving quality throughout the production process. By integrating product technology into every stage of the production process flow, manufacturers can achieve higher levels of precision, consistency, and creativity in paper decoration manufacturing, delivering unique and memorable decorations that delight customers and enhance interior spaces.