In the realm of paper decoration manufacturing, where creativity and craftsmanship converge, the role of production equipment cannot be overstated. From printing presses to cutting machines, each piece of equipment plays a crucial role in bringing intricate designs to life and ensuring the quality and precision of the final product. In this blog post, we'll explore the essential equipment used in paper decoration production, highlighting the advancements in Product technology that have revolutionized the industry.

The Significance of Paper decoration production equipment

Paper decoration production equipment forms the backbone of the manufacturing process, enabling manufacturers to transform raw materials into exquisitely crafted decorations that delight and enchant consumers. From design conception to final assembly, each piece of equipment contributes to the efficiency, precision, and quality of the production process.

In the competitive landscape of the paper decoration industry, investing in state-of-the-art equipment is essential for maintaining a competitive edge and meeting the evolving demands of customers. By leveraging advancements in Product technology and automation, manufacturers can streamline operations, minimize waste, and deliver decorations that exceed expectations.

Product technology: Driving Innovation in Paper Decoration Equipment

Advancements in Product technology have revolutionized the capabilities and functionalities of Paper decoration production equipment, offering solutions that enhance efficiency, precision, and versatility. From digital printing to laser cutting, these technological innovations have transformed the landscape of paper decoration manufacturing, enabling manufacturers to push the boundaries of creativity and craftsmanship.

Digital printing technology has emerged as a game-changer in the paper decoration industry, offering unparalleled flexibility, speed, and quality in reproducing intricate designs and vibrant colors on various substrates. Unlike traditional printing methods, digital printing eliminates the need for costly setup fees and allows for on-demand printing of small batch orders, making it ideal for customized and personalized decorations.

Laser cutting machines have also revolutionized the production process, offering precision, speed, and versatility in cutting intricate shapes and designs from paper and other materials. Equipped with high-powered lasers and advanced control systems, these machines can cut through a wide range of materials with remarkable accuracy, allowing manufacturers to create intricate and detailed decorations with ease.

Essential Paper decoration production equipment

Printing Presses:

Printing presses are essential for reproducing designs and patterns onto paper and other substrates. Digital printing presses offer flexibility and efficiency in producing vibrant and detailed decorations, while offset printing presses are ideal for high-volume production runs. These presses may feature advanced color calibration systems, automated registration controls, and inspection mechanisms to ensure consistent quality and accuracy.

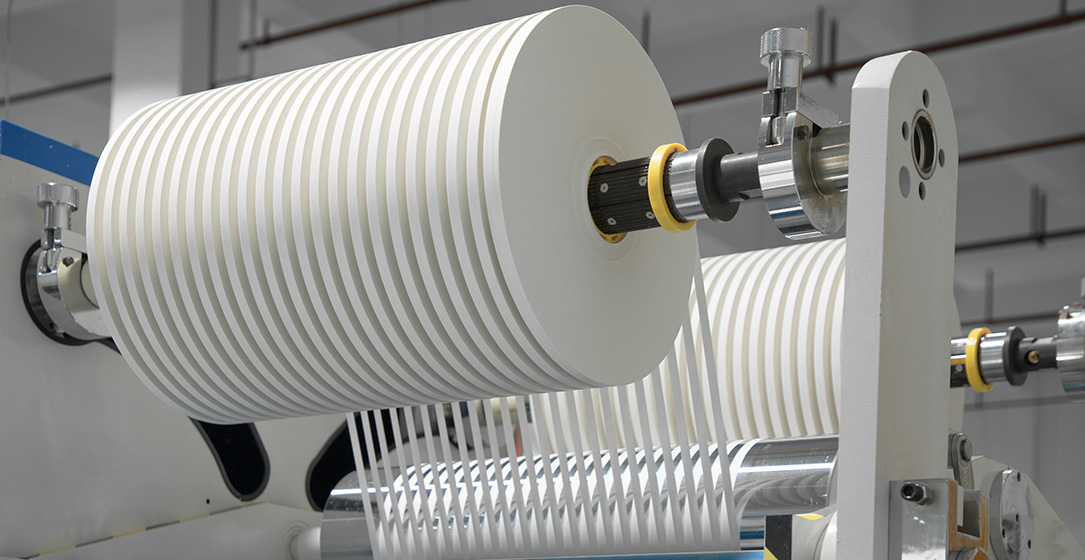

Cutting Machines:

Cutting machines, such as die cutters and laser cutters, are used to cut out intricate shapes and designs from paper and other materials. Die cutters utilize sharp blades and cutting dies to punch out shapes with precision, while laser cutters use high-powered lasers to cut through materials with remarkable accuracy. These machines may feature adjustable settings, automated feeding systems, and monitoring capabilities to optimize performance and minimize waste.

Folding and Scoring Machines:

Folding and scoring machines are used to create crisp folds and creases in paper decorations, ensuring uniformity and precision in assembly. These machines may feature adjustable settings for different types of folds and materials, as well as automated feeding systems and inspection mechanisms to ensure consistent quality.

Embossing and Foil Stamping Presses:

Embossing and foil stamping presses add texture and metallic accents to paper decorations, enhancing their visual appeal and sophistication. These presses use heat and pressure to transfer embossing dies or foil onto the paper, creating stunning effects that elevate the overall aesthetic of the decorations. They may feature adjustable settings, temperature controls, and precision alignment systems to achieve optimal results.

Packaging Equipment:

Packaging equipment, such as wrapping machines and labeling systems, are essential for packaging finished decorations for distribution and sale. Wrapping machines automate the process of enclosing decorations in protective packaging, while labeling systems add essential information such as product codes and branding to the packaging. These machines may feature adjustable settings, automated feeding systems, and inspection mechanisms to ensure efficient and consistent packaging.

Conclusion: Elevating Paper Decoration Manufacturing with Advanced equipment

In the dynamic and competitive landscape of paper decoration manufacturing, investing in advanced production equipment is essential for maintaining a competitive edge and delivering decorations that exceed expectations. From printing presses to cutting machines and packaging equipment, each piece of equipment plays a crucial role in bringing intricate designs to life and ensuring the quality and precision of the final product. By leveraging advancements in Product technology and automation, manufacturers can streamline operations, minimize waste, and deliver decorations that delight and enchant consumers, ensuring success in the ever-evolving market.