Understanding Paper Decoration Manufacturing

Before delving into the evolution of the market economy, it's essential to understand the basics of paper decoration manufacturing. Paper decoration involves the creation of aesthetically pleasing designs on various paper-based products, including but not limited to gift wrapping paper, greeting cards, wallpaper, and packaging materials. These decorations can range from simple prints to intricate patterns and textures, catering to diverse consumer preferences.

Early Days: Craftsmanship and Manual Labor

In the early stages of paper decoration production, craftsmanship and manual labor were the primary drivers. Skilled artisans meticulously crafted designs using basic tools such as brushes, stencils, and hand-carved blocks. While this artisanal approach ensured quality and uniqueness, it was inherently limited in terms of scalability and efficiency. Moreover, the labor-intensive nature of the process often resulted in higher production costs and longer lead times.

Technological Revolution: Introduction of Printing Presses

The advent of printing presses revolutionized the paper decoration manufacturing industry. With the invention of mechanized printing techniques such as offset printing and gravure printing, mass production became feasible. These technologies enabled manufacturers to produce large quantities of decorated paper products rapidly and cost-effectively. As a result, the market witnessed a surge in supply, catering to growing consumer demand for decorative paper items.

Product Technology: Innovations in Printing and Design

Product technology played a crucial role in driving the evolution of paper decoration manufacturing. Continuous advancements in printing technology, including digital printing and laser printing, empowered manufacturers to achieve unparalleled precision and detail in their designs. High-resolution printing capabilities allowed for the replication of intricate patterns and vibrant colors, enhancing the visual appeal of paper decorations.

Moreover, the integration of computer-aided design (CAD) software facilitated the creation of custom designs and personalized decorations. This customization capability not only expanded the creative possibilities but also enabled manufacturers to cater to niche markets and individual preferences effectively. Furthermore, innovations in eco-friendly printing technologies and sustainable materials have addressed growing concerns regarding environmental impact, aligning with consumer preferences for sustainable products.

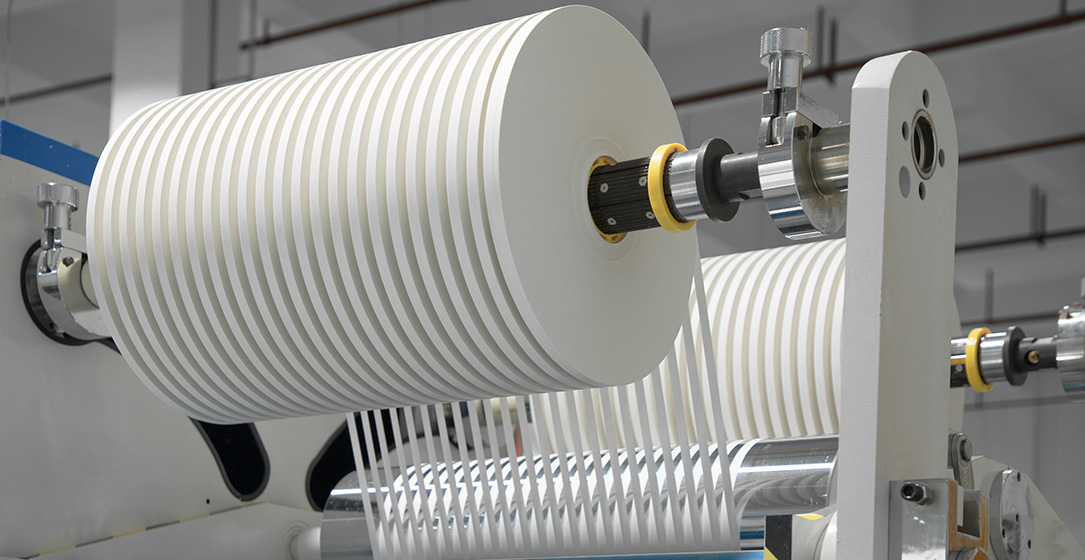

Paper Decoration Equipment: Automation and Efficiency

In tandem with product technology advancements, paper decoration equipment has undergone significant evolution to enhance automation and efficiency in the manufacturing process. Automated printing presses equipped with advanced control systems and robotics have streamlined production workflows, reducing manual intervention and minimizing the risk of errors. Additionally, the integration of smart sensors and IoT (Internet of Things) connectivity has enabled real-time monitoring of equipment performance, optimizing maintenance schedules, and minimizing downtime.

Furthermore, the development of modular and customizable equipment solutions has empowered manufacturers to adapt quickly to changing market demands and production requirements. Whether it's a small-scale printing operation or a large industrial facility, paper decoration equipment manufacturers offer a diverse range of solutions tailored to specific needs and budget constraints.

Market Dynamics: Globalization and Diversification

The evolution of the market economy in paper decoration production has been influenced by broader market dynamics, including globalization and diversification. As supply chains become increasingly interconnected, manufacturers have access to a global marketplace for raw materials, technology, and expertise. This globalization has facilitated the exchange of ideas and best practices, driving innovation and competition within the industry.

Moreover, the diversification of consumer preferences and emerging market trends have prompted manufacturers to explore new product categories and design concepts. From decorative packaging for e-commerce shipments to bespoke wedding invitations, the demand for paper decorations extends across various sectors and occasions. As a result, manufacturers must remain agile and adaptable to capitalize on emerging opportunities and stay ahead of the curve.

Future Outlook: Innovation and Sustainability

Looking ahead, the future of paper decoration manufacturing promises continued innovation and sustainability. Advancements in materials science, such as bio-based inks and recyclable substrates, will further enhance the eco-friendliness of paper decorations, aligning with evolving consumer preferences for sustainable products.

Furthermore, the convergence of digital technology and traditional craftsmanship presents exciting possibilities for the industry. Augmented reality (AR) and virtual reality (VR) experiences integrated into paper decorations can offer immersive and interactive storytelling, enhancing consumer engagement and brand loyalty.

In conclusion, the development of the market economy in paper decoration production has been shaped by technological advancements, product innovation, and shifting consumer dynamics. As the industry continues to evolve, manufacturers must embrace innovation, sustainability, and adaptability to thrive in an increasingly competitive marketplace. By leveraging cutting-edge technology and embracing creative ingenuity, the future of paper decoration manufacturing is bright and full of possibilities.