In a world where customization is increasingly valued, even the simplest of items can become a canvas for individual expression. Paper decoration manufacturing, once relegated to generic designs, have now entered the realm of personalized craftsmanship. This evolution is not only driven by consumer demand but also by advancements in manufacturing technology. In this blog post, we'll explore the fascinating world of customized production in Paper decoration manufacturing, delving into the manufacturing processes, product technology, and the equipment that make it all possible.

The Rise of customization in Paper decoration manufacturing

Gone are the days when Paper decoration manufacturing were mass-produced in identical patterns and colors. Today, consumers crave uniqueness, seeking products that reflect their personal style and preferences. This shift has prompted manufacturers to adopt innovative approaches to meet the growing demand for customized Paper decoration manufacturing.

Manufacturing Process

The manufacturing process of customized Paper decoration manufacturing involves several intricate steps, each contributing to the final product's quality and uniqueness.

Design Creation: The journey begins with the creation of designs. Thanks to advancements in graphic design software, designers can unleash their creativity, crafting intricate patterns, motifs, and themes tailored to specific occasions or preferences. Whether it's a whimsical floral design for a wedding or a playful motif for a children's party, the possibilities are endless.

Material Selection: The choice of paper is crucial in determining the appearance and durability of the decorations. Manufacturers select papers of various weights, textures, and finishes to achieve the desired aesthetic and structural integrity. From lightweight tissue paper to sturdy cardstock, each material lends itself to different types of decorations, whether it be delicate hanging ornaments or robust centerpieces.

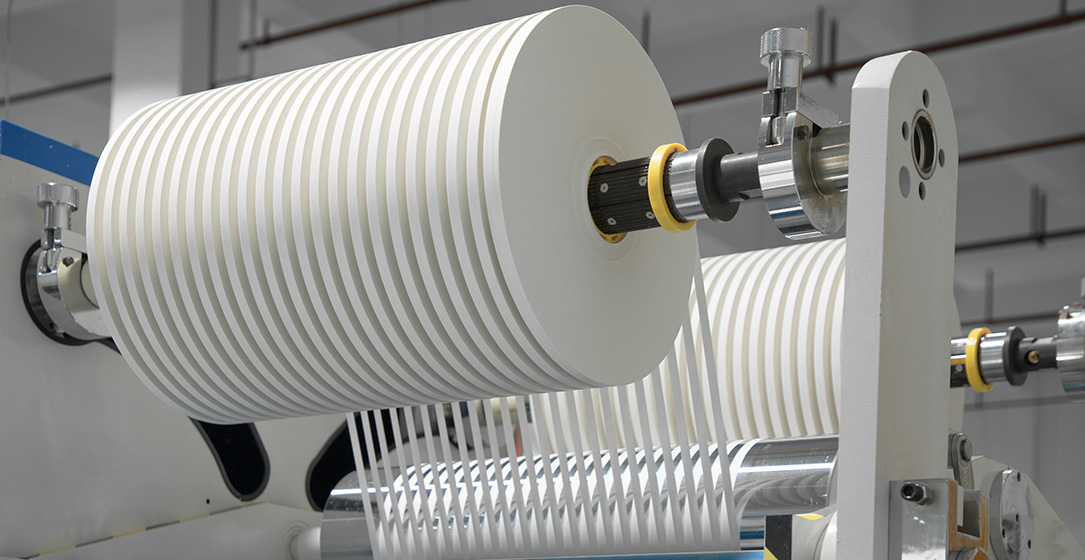

Printing and Cutting: With the designs finalized and the materials chosen, the next step involves printing the patterns onto the selected paper. Advanced printing technologies, such as digital and offset printing, ensure precise reproduction of intricate details and vibrant colors. Once printed, the paper is then fed into cutting machines equipped with precision blades, which meticulously cut out the shapes according to the design specifications.

Assembly and Finishing: Depending on the complexity of the decorations, assembly may involve intricate folding, scoring, and gluing techniques. Skilled artisans meticulously craft each piece, ensuring precision and attention to detail. Finishing touches such as embellishments, foil stamping, or embossing add an extra layer of sophistication, elevating the decorations from ordinary to extraordinary.

Product Technology

Behind the scenes, technology plays a pivotal role in enabling the customization of Paper decoration manufacturing. From design software to cutting-edge manufacturing equipment, here are some key technologies driving innovation in the industry:

CAD Software: Computer-aided design (CAD) software empowers designers to create intricate patterns and motifs with unparalleled precision. These software tools offer a wide range of features, including 3D modeling, pattern generation, and simulation, allowing designers to bring their visions to life with ease.

Digital Printing: Digital printing technology revolutionizes the printing process, enabling quick turnaround times and cost-effective production of small batch orders. Unlike traditional printing methods, digital printing eliminates the need for costly setup fees and allows for on-demand printing, making it ideal for customized products.

CNC Cutting Machines: Computer Numerical Control (CNC) cutting machines automate the cutting process with remarkable accuracy. Equipped with high-speed rotary blades or laser cutters, these machines precisely cut out intricate shapes and patterns from various materials, ensuring consistency and efficiency in production.

RFID Technology: Radio-frequency identification (RFID) technology is increasingly integrated into Paper decoration manufacturing for inventory management and tracking purposes. By embedding RFID tags into the products, manufacturers can monitor their whereabouts throughout the supply chain, streamline logistics, and prevent loss or theft.

Paper decoration manufacturing Equipment

Behind every exquisitely crafted Paper decoration manufacturing lies a suite of specialized equipment designed to streamline the paper manufacturing process. Here are some essential pieces of equipment used in the production of Paper decoration manufacturing:

Printing Presses: Offset printing presses are commonly used for high-volume production of Paper decoration manufacturing. These presses utilize metal plates to transfer ink onto paper, ensuring consistent color reproduction and sharp image quality.

Die Cutting Machines: Die cutting machines are essential for cutting out intricate shapes and designs from paper. These machines come in various configurations, including manual, semi-automatic, and fully automatic models, catering to different production requirements.

Folding and Scoring Machines: Folding and scoring machines automate the process of creating crisp folds and creases in Paper decoration manufacturing. These machines feature adjustable settings for precise folding, ensuring uniformity across the entire production run.

Embossing and Foil Stamping Presses: Embossing and foil stamping presses add luxurious textures and metallic accents to Paper decoration manufacturing. These presses use heat and pressure to transfer foil or embossing dies onto the paper, creating stunning visual effects that enhance the overall aesthetic appeal.

In conclusion, the customized production of Paper decoration manufacturing represents the perfect marriage of artistry and technology. From design creation to manufacturing processes and equipment, every aspect of the production journey contributes to the creation of unique and personalized decorations that delight consumers around the world. As technology continues to advance, the possibilities for customization are endless, ensuring that Paper decoration custom manufacturing will remain a cherished and versatile medium for self-expression for years to come.