Introduction:

In the world of interior design, paper decorations have emerged as versatile and eco-friendly accents that add personality and charm to any space. Behind the scenes of crafting these intricate creations lies a dynamic landscape of production technology, where innovation drives efficiency, creativity, and quality. In this blog, we explore the latest advancements in production Technology for paper decorations, from digital printing to automated assembly lines, and their impact on Paper decoration manufacturing.

The Evolution of Production Technology:

The production technology for paper decorations has undergone a significant evolution in recent years, driven by Advancements in digital printing, die-cutting machines, and automation. These technologies have revolutionized the way paper decorations are designed, produced, and assembled, leading to higher levels of efficiency, precision, and Creativity.

Digital Printing Technology:

One of the most transformative advancements in production technology for paper decorations is digital printing. Digital printing technology allows manufacturers to reproduce intricate designs with stunning clarity and detail, offering endless possibilities for customization and personalization.

With digital printing, manufacturers can achieve vibrant colors, sharp details, and smooth gradients, creating eye-catching designs that captivate the imagination. Moreover, digital printing eliminates the need for traditional printing plates, reducing setup costs and lead times, and enabling quick turnaround times for custom orders.

Die-Cutting Machines:

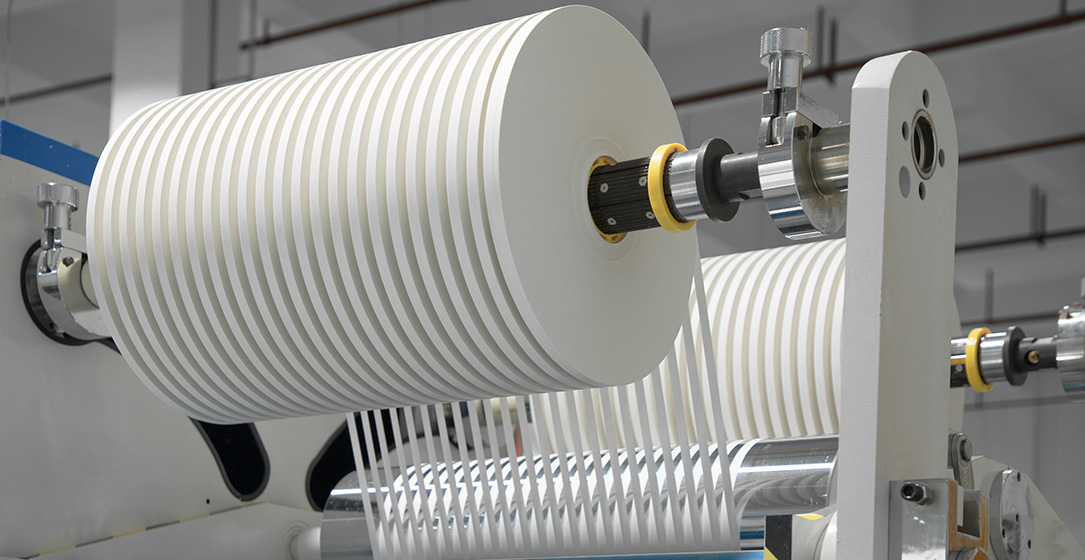

Die-cutting machines have also played a crucial role in advancing production technology for paper decorations. These machines use custom-made dies to cut intricate shapes and designs from paper, offering unparalleled precision and consistency.

With advancements in die-cutting technology, manufacturers can produce complex designs with ease, from delicate lace patterns to intricate floral motifs. Moreover, die-cutting machines can handle a wide range of materials, including cardstock, vellum, and specialty papers, allowing for versatility and creativity in design.

Automated Assembly Lines:

In addition to digital printing and die-cutting machines, Automated assembly lines have revolutionized the production process for paper decorations. These assembly lines streamline the assembly process, enabling seamless production from start to finish.

Automated assembly lines are equipped with folding and gluing machines, automated feeders, and robotic arms, allowing for efficient and precise assembly of paper decorations. By automating repetitive tasks, manufacturers can minimize labor costs, reduce cycle times, and improve overall efficiency.

Impact on Paper Decoration Manufacturing:

The advancements in production technology have had a profound impact on paper decoration manufacturing, enabling manufacturers to achieve higher levels of efficiency, precision, and creativity. With digital printing, manufacturers can produce custom designs with minimal setup time, allowing for quick turnaround times and reduced lead times for custom orders.

Die-cutting machines have also revolutionized the design process, allowing manufacturers to create intricate shapes and designs that were previously impossible with traditional methods. Moreover, automated assembly lines have streamlined the production process, reducing labor costs and improving overall efficiency.

Furthermore, advancements in production technology have opened up new possibilities for innovation and creativity in paper decoration manufacturing. Manufacturers can experiment with new materials, techniques, and designs, pushing the boundaries of what is possible in paper decoration design.

Future Trends and Innovations:

Looking ahead, the future of production technology for paper decorations is ripe with possibilities. Advancements in digital printing technology, such as the development of faster printers and eco-friendly inks, will continue to drive efficiency and Sustainability in paper decoration manufacturing.

Moreover, the integration of artificial intelligence and machine learning algorithms into production technology will enable manufacturers to optimize production processes, minimize waste, and improve quality control. Additionally, the adoption of 3D printing technology may open up new avenues for creativity and customization in paper decoration design.

Conclusion:

In conclusion, innovation in production technology has revolutionized the way paper decorations are designed, produced, and assembled. From digital printing to die-cutting machines to automated assembly lines, these advancements have enabled manufacturers to achieve higher levels of efficiency, precision, and creativity in paper decoration manufacturing.

As the industry continues to evolve, the future of production technology for paper decorations holds exciting possibilities for innovation and creativity. By embracing these advancements, manufacturers can stay ahead of the curve, meet customer expectations, and drive growth and success in the dynamic world of paper decoration manufacturing.