In the realm of paper decorations, where every fold and cut tells a story of creativity and craftsmanship, ensuring quality is paramount. From intricate designs to vibrant colors, every aspect of a paper decoration must meet exacting standards to delight customers and uphold the reputation of the brand. In this blog post, we'll explore the importance of Quality control in Paper decoration manufacturing, examining the role of Product technology, Paper decoration equipment, and Meticulous processes in ensuring excellence.

The Significance of Quality control in Paper decoration manufacturing

Quality control is the cornerstone of Paper decoration manufacturing, encompassing a range of processes and procedures designed to maintain consistency, accuracy, and reliability throughout the production process. From the selection of raw materials to the final inspection of finished products, every step is meticulously scrutinized to ensure that only the highest quality decorations reach the hands of customers.

In the competitive landscape of the paper decoration industry, quality is not just a hallmark of excellence but also a key differentiator that sets brands apart from their competitors. By prioritizing Quality control, manufacturers can build trust with customers, establish a reputation for reliability, and ultimately drive long-term success in the market.

Product technology: Enhancing Precision and Consistency

Product technology plays a crucial role in facilitating Quality control in Paper decoration manufacturing, offering tools and solutions that enhance precision, consistency, and efficiency throughout the production process. From design software to automated inspection systems, these technological advancements empower manufacturers to maintain stringent quality standards at every stage of production.

Computer-aided design (CAD) software enables designers to create intricate patterns and motifs with unparalleled precision, ensuring that every detail is meticulously crafted to perfection. These digital tools allow for real-time adjustments and modifications, facilitating seamless collaboration between designers and production teams to achieve the desired aesthetic and functionality.

In the realm of printing technology, advancements such as digital printing and color management systems ensure consistent color reproduction and image quality across various substrates and production runs. These technologies minimize deviations and variations, guaranteeing that each decoration meets the specified color standards and brand guidelines.

Paper decoration equipment: Enabling Precision and Efficiency

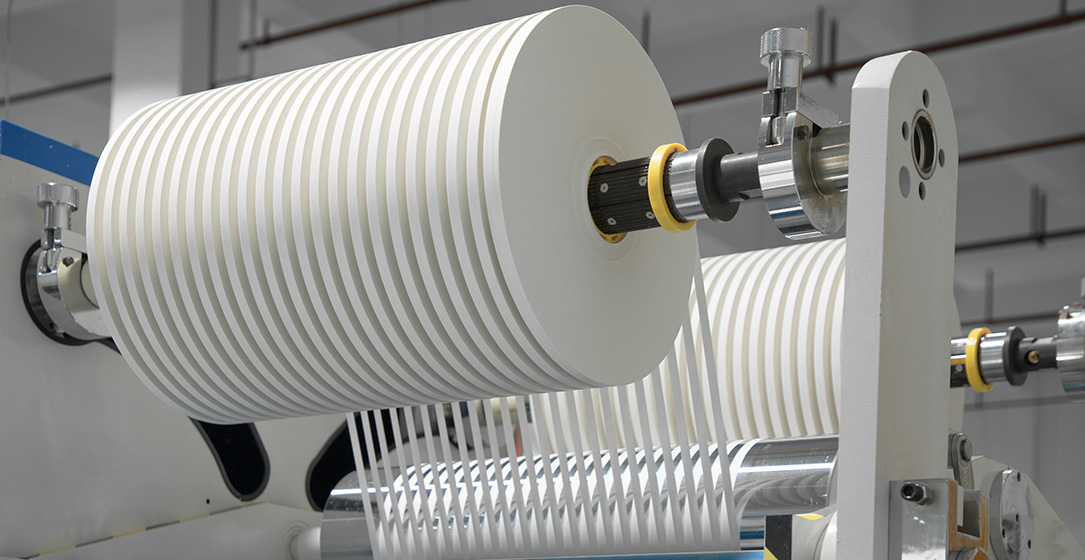

Behind every exquisitely crafted paper decoration lies a suite of specialized equipment designed to enable precision, efficiency, and consistency in manufacturing. From printing presses to cutting machines, each piece of equipment plays a crucial role in the Quality control process, ensuring that decorations meet exacting standards from start to finish.

Printing presses equipped with advanced color calibration systems and automated registration controls ensure accurate color reproduction and alignment, minimizing errors and inconsistencies in printed decorations. These presses also feature inspection and monitoring capabilities that allow operators to detect and address defects in real time, ensuring that only flawless decorations proceed to the next stage of production.

Cutting machines, such as die cutters and laser cutters, enable manufacturers to achieve precise cuts and shapes with remarkable accuracy, minimizing waste and ensuring uniformity across all decorations. These machines are equipped with sensors and feedback mechanisms that monitor cutting performance and detect deviations from the specified parameters, enabling timely adjustments and corrections to maintain quality standards.

Meticulous processes: From Inspection to Packaging

In addition to technological advancements and specialized equipment, Meticulous processes and procedures are essential for Quality control in Paper decoration manufacturing. From incoming inspection of raw materials to final inspection of finished products, each step is carefully orchestrated to identify and address any issues that may compromise quality.

Incoming inspection involves rigorous testing and evaluation of raw materials, such as paper and adhesives, to ensure that they meet the specified quality standards and performance criteria. Any deviations or deficiencies are documented and addressed promptly to prevent them from affecting the quality of the final product.

Throughout the production process, in-process inspections are conducted at key checkpoints to monitor quality and identify any deviations from the specified parameters. These inspections may involve visual checks, dimensional measurements, and functional testing to ensure that decorations meet the required standards of appearance, performance, and durability.

Finally, before packaging and shipping, finished products undergo a comprehensive final inspection to verify that they meet all quality criteria and specifications. Any decorations that fail to meet the required standards are rejected or reworked to rectify any defects before being released for distribution.

Upholding Excellence in Paper decoration manufacturing

In the world of paper decorations, Quality control is not just a process – it's a commitment to excellence that shapes every aspect of production. By leveraging Product technology, specialized equipment, and Meticulous processes, manufacturers can ensure that every decoration meets the highest standards of quality, reliability, and aesthetics. From the design studio to the production floor, Quality control is woven into the fabric of every operation, ensuring that customers receive decorations that exceed their expectations and delight their senses.