Paper decorations, with their versatility and charm, have become a staple in various settings, from weddings to home décor and festive celebrations. Behind their delicate beauty lies a complex process of production, where every fold and cut represents not just creativity but also economic considerations. In this blog post, we'll delve into the intricacies of the Production costs of paper decorations, exploring the manufacturing process, the role of Product technology, and the investments required in paper decoration equipment to bring these exquisite creations to life.

The Economics of Paper decoration manufacturing

Before diving into the specifics of Production costs, it's essential to understand the broader economic landscape of Paper decoration manufacturing. Like any other industry, the production of paper decorations is subject to factors such as raw material prices, labor costs, overhead expenses, and market demand.

Raw materials, primarily paper, constitute a significant portion of the Production costs. The type and quality of paper used can vary depending on the design and intended use of the decorations. While standard paper varieties are more economical, specialty papers with unique textures or finishes may command a higher price.

Labor costs also play a crucial role, particularly in intricate designs that require skilled craftsmanship. From design creation to assembly and packaging, each step of the production process involves human labor, which adds to the overall cost of production.

Overhead expenses, including rent, utilities, and administrative costs, further contribute to the total Production costs. These fixed expenses must be factored into the pricing strategy to ensure profitability and sustainability.

Product technology: Balancing Innovation and Costs

Innovation in Product technology has revolutionized the production process of paper decorations, offering opportunities to enhance efficiency and quality while mitigating costs. From digital design tools to automated manufacturing equipment, these technological advancements play a crucial role in optimizing Production costs.

Computer-aided design (CAD) software allows designers to create intricate patterns and motifs with unparalleled precision, streamlining the design process and reducing the need for manual labor. Advanced printing technologies, such as digital and offset printing, offer cost-effective solutions for producing vibrant and detailed designs without the setup costs associated with traditional printing methods.

Automation has also transformed the manufacturing process, reducing labor costs and increasing productivity. CNC cutting machines and robotic assembly systems enable manufacturers to produce paper decorations with remarkable speed and accuracy, minimizing waste and maximizing efficiency.

While investing in Product technology may require an initial upfront investment, the long-term cost savings and quality improvements often outweigh the initial costs. By leveraging technology to optimize production processes, manufacturers can achieve greater economies of scale and maintain a competitive edge in the market.

paper decoration equipment: Investing in Efficiency

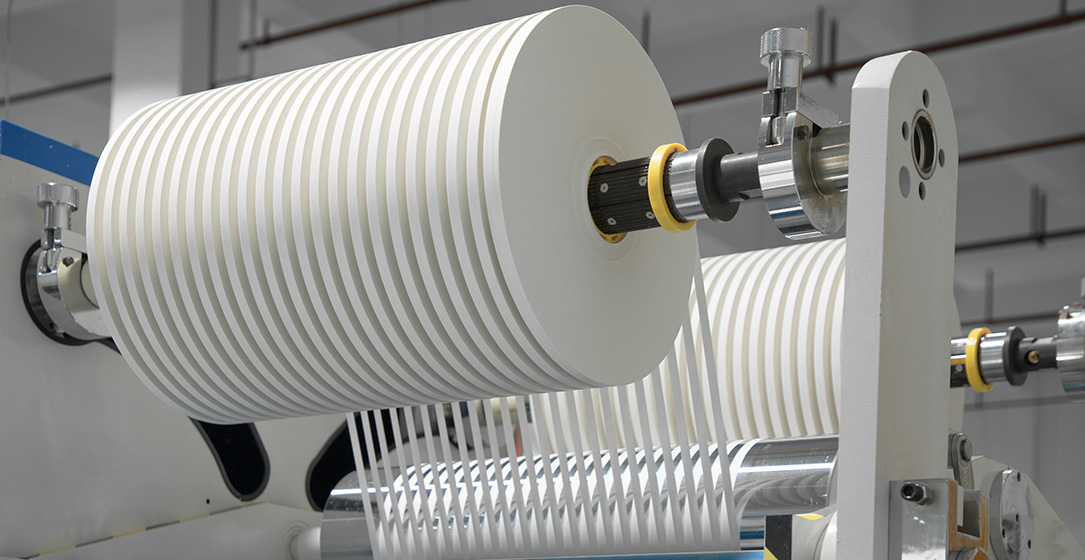

Behind every exquisitely crafted paper decoration lies a suite of specialized equipment designed to streamline the production process and ensure consistency in quality. From printing presses to cutting machines, each piece of equipment represents a significant investment that must be carefully considered in the overall cost structure.

Printing presses, whether digital or offset, are essential for reproducing intricate designs and vibrant colors on paper. The choice between these two technologies depends on factors such as print volume, speed, and cost-effectiveness. While digital printing offers greater flexibility for small batch orders and customization, offset printing may be more cost-effective for larger production runs.

Cutting machines, such as die cutters and laser cutters, are indispensable for achieving precise cuts and shapes in paper decorations. These machines require careful calibration and maintenance to ensure optimal performance and minimize material waste.

In addition to production equipment, packaging machinery is also a critical investment in the overall cost structure. Wrapping machines, labeling systems, and automated packaging solutions help streamline the packaging process, reducing labor costs and ensuring consistency in presentation.

Strategies for Cost optimization

In a competitive market landscape, Cost optimization is essential for maintaining profitability and sustainability in Paper decoration manufacturing. Here are some strategies to consider:

Bulk Purchasing: Buying raw materials, such as paper and adhesives, in bulk can help reduce unit costs and minimize waste.

Lean Manufacturing: Implementing lean manufacturing principles, such as just-in-time production and waste reduction techniques, can help minimize inefficiencies and maximize productivity.

Outsourcing: Outsourcing certain production processes, such as printing or packaging, to specialized vendors can help reduce overhead expenses and focus internal resources on core competencies.

Continuous Improvement: Regularly evaluating and optimizing production processes can help identify areas for cost savings and efficiency improvements.

Value Engineering: Analyzing the design and construction of paper decorations to identify opportunities for cost reduction without compromising quality or aesthetics.

Conclusion: Navigating the Economics of Paper Decoration Production

The Production costs of paper decorations are a multifaceted equation influenced by raw material prices, labor costs, overhead expenses, and investments in Product technology and equipment. By understanding the economic factors at play and implementing strategies for Cost optimization, manufacturers can achieve greater efficiency, profitability, and competitiveness in the market. Ultimately, striking the right balance between innovation and cost-effectiveness is essential for delivering high-quality paper decorations that enchant and delight consumers while ensuring the sustainability of the business in the long run.