Sustainability | Innovation

Get a Quote

or call +852 9742 1492

Home >

News >

Enhancing Production Efficiency in Paper Decoration Manufacturing: A Technological Journey

Company News

Enhancing Production Efficiency in Paper Decoration Manufacturing: A Technological Journey

This article examines how production efficiency drives success in paper decoration manufacturing. It highlights the use of technology, equipment, and strategic management to optimize processes. Key points include leveraging digital printing and design software, utilizing specialized equipment like die-cutting machines and automation, and emphasizing environmental sustainability. Overall, the article emphasizes the importance of innovation and efficiency in the industry.

Published by

at

Tuesday 01, 2023

Introduction:

In the realm of interior decoration, paper decorations have become synonymous with charm, creativity, and versatility. From delicate origami sculptures to vibrant paper garlands, these adornments add a touch of whimsy to any space. However, behind the scenes of their enchanting allure lies a complex process of manufacturing that requires meticulous attention to detail and advanced technology. In this blog, we explore the pivotal role of production efficiency in Paper decoration manufacturing, delving into the nuances of product technology, equipment, and strategies that contribute to streamlining operations and maximizing output.

Optimizing Paper Decoration Manufacturing Processes:

The journey of crafting paper decorations begins with the selection of high-quality materials and the design phase, where creativity intertwines with practicality. Once the design is finalized, the focus shifts towards optimizing production processes to ensure efficiency without compromising on quality. Key aspects such as product technology, equipment utilization, and workflow management play a crucial role in achieving production efficiency.Leveraging Product Technology:

Advancements in Product technology have revolutionized the landscape of paper decoration manufacturing, offering innovative solutions to streamline production processes and enhance overall efficiency. Digital printing stands out as a cornerstone technology in this domain, enabling manufacturers to reproduce intricate designs with unparalleled precision and speed. By harnessing the power of digital printing, companies can cater to diverse customer preferences, produce customized decorations on demand, and significantly reduce turnaround times.Moreover, advancements in digital design software facilitate seamless integration between design and production stages, allowing for swift modifications and adjustments based on evolving market trends and client requirements. This integration enhances workflow efficiency and minimizes potential errors, ensuring a smoother transition from concept to finished product.

Empowering Paper Decoration Equipment:

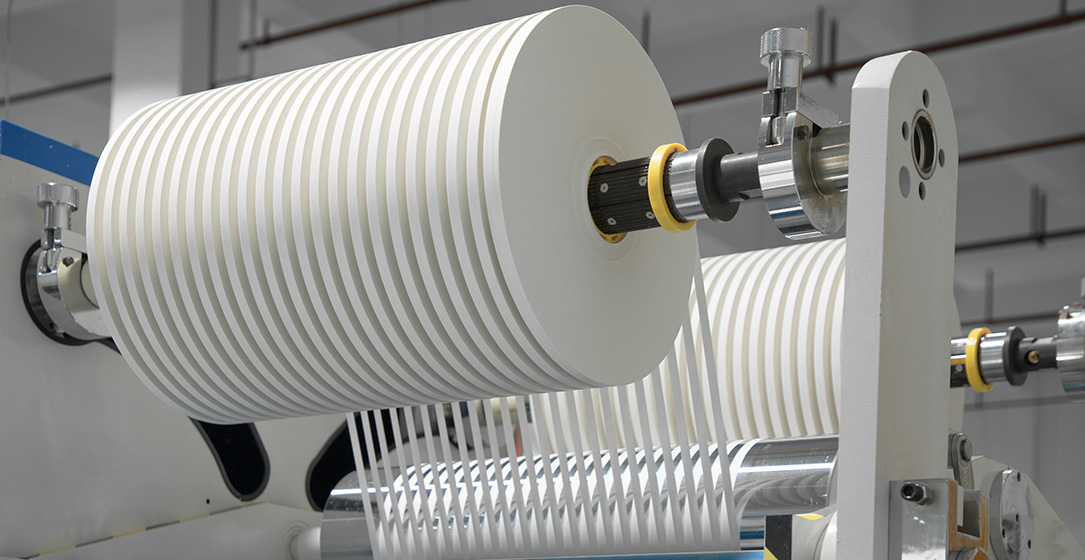

The role of specialized equipment in paper decoration manufacturing cannot be overstated. From cutting-edge die-cutting machines to automated folding and gluing systems, these tools are instrumental in shaping and assembling intricate paper creations with precision and consistency. Die-cutting machines, in particular, play a pivotal role in producing uniform shapes and designs, minimizing material waste and optimizing production throughput.Furthermore, investing in state-of-the-art equipment tailored to the specific needs of paper decoration manufacturing enhances operational efficiency and reduces dependency on manual labor. Automated assembly lines equipped with robotic arms and conveyor systems further streamline production processes, minimizing downtime and maximizing output capacity. By embracing automation, companies can achieve higher levels of efficiency while maintaining stringent quality standards.

Strategies for Streamlined Operations:

In addition to leveraging advanced technology and equipment, implementing strategic Workflow management practices is essential for optimizing production efficiency in paper decoration manufacturing. Adopting lean manufacturing principles, such as just-in-time inventory management and continuous process improvement, helps minimize waste, reduce production lead times, and enhance overall productivity.Furthermore, establishing clear communication channels and fostering collaboration among different departments within the manufacturing facility promotes synergy and facilitates seamless coordination throughout the production cycle. Regular performance evaluations and data-driven analytics enable companies to identify bottlenecks, inefficiencies, and areas for improvement, thereby facilitating informed decision-making and driving continuous optimization efforts.

Environmental Considerations and Sustainability:

While pursuing production efficiency is paramount, it is equally essential for paper decoration manufacturers to prioritize Environmental sustainability. Adopting eco-friendly materials, such as recycled paper and biodegradable inks, minimizes environmental impact and aligns with growing consumer preferences for sustainable products. Additionally, implementing energy-efficient practices and waste management systems helps reduce carbon footprint and promotes responsible stewardship of natural resources.

Conclusion:

In the ever-evolving landscape of paper decoration manufacturing, enhancing production efficiency is key to staying competitive and meeting the demands of an increasingly discerning market. By leveraging cutting-edge product technology, optimizing equipment utilization, and implementing streamlined workflow management practices, companies can streamline operations, boost productivity, and deliver high-quality decorations in a timely manner. Moreover, prioritizing environmental sustainability underscores a commitment to ethical business practices and resonates with eco-conscious consumers. As the industry continues to evolve, embracing innovation and efficiency will be paramount in shaping the future of paper decoration manufacturing, ensuring continued success and relevance in a dynamic marketplace.

Get The Personalized Solution

A complete solution for your paper product manufacturing is available now!

Yours is the most important voice. If you have any questions or comments for us, please use the form below to send them to us. Thanks!