Introduction:

In the world of interior decoration, paper adornments have emerged as popular choices, offering versatility, charm, and eco-friendliness. Behind the allure of these whimsical decorations lies the importance of Production standards—a set of guidelines and benchmarks that ensure consistency, quality, and efficiency in the manufacturing process. In this blog, we delve into the significance of production standards for paper decorations, exploring their role in optimizing manufacturing processes, integrating product technology, and maximizing the effectiveness of paper decoration equipment.

The Importance of Production Standards:

Production standards serve as the foundation of excellence in Paper decoration manufacturing, providing a framework for consistency, quality, and efficiency. By establishing clear guidelines and benchmarks, manufacturers can ensure that each step of the production process meets predetermined criteria for performance and excellence. From material selection to final assembly, adherence to production standards is essential to delivering paper decorations of exceptional quality and craftsmanship.

Optimizing Manufacturing Processes:

Central to the establishment of production standards is the optimization of Manufacturing processes—a systematic approach to streamlining operations, minimizing waste, and maximizing efficiency. By analyzing each step of the production process, manufacturers can identify opportunities for improvement, implement best practices, and standardize procedures to ensure consistent results.

Product technology plays a crucial role in optimizing manufacturing processes, offering opportunities to automate repetitive tasks, minimize errors, and enhance precision. Digital printing technology, for example, enables manufacturers to reproduce intricate designs with unparalleled accuracy, reducing the need for manual intervention and minimizing material waste. By integrating product technology into manufacturing processes, manufacturers can achieve higher levels of efficiency and productivity while maintaining stringent quality standards.

Integrating Product Technology:

In an era defined by technological innovation, the integration of Product technology has become essential to the success of paper decoration manufacturing. From digital design software to automated production equipment, product technology offers opportunities to enhance creativity, streamline processes, and deliver superior results.

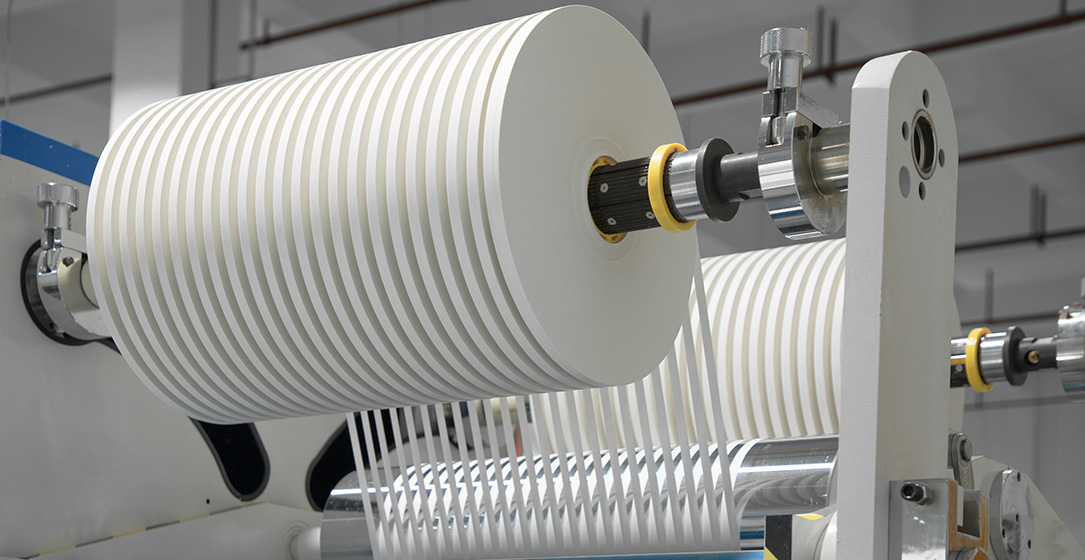

Die-cutting machines stand out as a transformative technology in paper decoration manufacturing, enabling manufacturers to cut intricate shapes and designs with precision and consistency. Equipped with custom-made dies and advanced cutting mechanisms, these machines minimize material waste and maximize productivity, ensuring uniformity across each piece.

Moreover, advancements in digital printing technology have revolutionized the production of paper decorations, enabling manufacturers to reproduce complex designs with stunning clarity and detail. By leveraging digital design software and high-resolution printing equipment, manufacturers can create visually striking decorations that captivate the imagination and elevate the aesthetic appeal of any space.

Maximizing the Effectiveness of Paper Decoration Equipment:

Specialized equipment plays a crucial role in the manufacturing of paper decorations, from die-cutting machines to folding and gluing equipment. To ensure the effectiveness of paper decoration equipment, manufacturers must establish clear performance standards, conduct regular maintenance, and provide comprehensive training to operators.

Regular maintenance schedules, preventative maintenance measures, and equipment calibration procedures are essential to ensure the longevity and performance of paper decoration equipment. By investing in equipment upgrades and implementing efficiency-improving measures, manufacturers can optimize production processes, minimize downtime, and enhance overall productivity.

Quality Control and Assurance:

Adherence to production standards is paramount to maintaining rigorous Quality control and assurance measures throughout the manufacturing process. By implementing standardized inspection procedures, manufacturers can identify defects, deviations, and inconsistencies at each stage of production, ensuring that only high-quality paper decorations reach the hands of customers.

Collaboration and Continuous Improvement:

The establishment of production standards fosters a culture of collaboration and continuous improvement within the organization. By involving employees in the development and implementation of production standards, manufacturers can harness the collective expertise and insights of their workforce to drive innovation, efficiency, and excellence.

Conclusion:

In conclusion, the establishment of production standards is essential to optimizing manufacturing processes, integrating product technology, and maximizing the effectiveness of paper decoration equipment. By setting clear guidelines and benchmarks for consistency, quality, and efficiency, manufacturers can ensure that each paper decoration meets the highest standards of craftsmanship and excellence. As the industry continues to evolve, adherence to production standards will be crucial to maintaining competitiveness, meeting customer expectations, and driving success in the dynamic world of paper decoration manufacturing.