Introduction:

In the realm of paper decoration production, creativity meets craftsmanship to bring forth intricate designs that adorn various occasions and spaces with charm and elegance. From whimsical party decorations to sophisticated home décor accents, paper decorations add a touch of artistry to any setting. In this blog, we'll delve into the fascinating world of paper decoration production and sales, exploring the manufacturing process, innovative product technologies, and the essential equipment that drives this thriving industry forward.

Understanding Paper Decoration Production:

Paper decoration production involves the meticulous crafting of paper into various forms, shapes, and designs to create decorative items used for a myriad of purposes. Whether it's vibrant paper garlands, delicate origami ornaments, or elaborate paper flowers, the production process requires a blend of creativity, precision, and technical expertise. From conceptualizing designs to selecting materials, cutting, folding, and assembling, each step contributes to the creation of visually stunning paper decorations.

Key Components of Paper Decoration Manufacturing:

- Design Conceptualization:

The journey of paper decoration production begins with design conceptualization, where artists and designers unleash their creativity to envision captivating designs. Whether drawing inspiration from nature, culture, or current trends, designers sketch out designs that reflect aesthetic appeal and artistic expression. Advanced design software allows for digital rendering and customization, enabling designers to bring their visions to life with precision.

- Material Selection:

Choosing the right materials is crucial for paper decoration production, as it impacts the quality, durability, and visual appeal of the final products. Manufacturers carefully select paper types, weights, colors, and textures based on design requirements and desired outcomes. From lightweight tissue paper to sturdy cardstock, each material offers unique properties that contribute to the overall look and feel of the paper decorations.

- Production Techniques:

Paper decoration production encompasses a variety of production techniques, including cutting, folding, shaping, and assembling. Advanced machinery such as die-cutting machines, laser cutters, and embossing machines streamline the production process, allowing for precise and efficient manufacturing. Skilled artisans may also employ traditional handcrafting techniques, adding a personal touch and artisanal quality to the finished products.

- Product Technology:

Innovations in product technology have revolutionized the paper decoration production industry, enabling manufacturers to create intricate designs with unparalleled precision and efficiency. Computer-aided design (CAD) software allows for intricate pattern creation and customization, while automated machinery ensures consistent quality and production output. 3D printing technology opens up new possibilities for creating complex three-dimensional paper structures, pushing the boundaries of creativity in paper decoration production.

- Quality Assurance:

Maintaining high standards of quality is paramount in paper decoration production to ensure that products meet customer expectations and stand the test of time. Quality assurance processes involve rigorous testing and inspection of materials, components, and finished products to identify any defects or inconsistencies. Manufacturers may implement quality control measures such as color matching, dimensional accuracy checks, and durability testing to uphold product quality and reliability.

Paper Decoration Equipment:

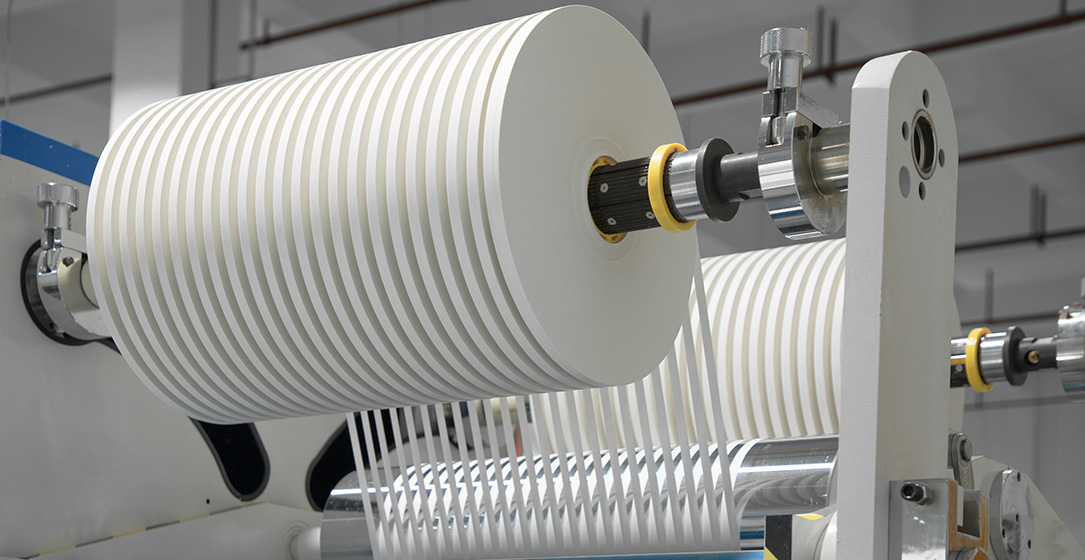

- Die-Cutting Machines:

Die-cutting machines are essential equipment in paper decoration production, used to cut intricate shapes, patterns, and designs from paper sheets with precision. These machines utilize metal dies or cutting blades to create clean and accurate cuts, allowing for efficient production of various paper decorations such as banners, tags, and embellishments.

- Laser Cutters:

Laser cutters offer precision cutting capabilities, allowing manufacturers to create intricate designs with intricate details and fine lines. These machines use laser technology to precisely cut through paper materials, enabling the production of delicate paper decorations such as lace-like motifs, intricate patterns, and decorative overlays.

- Embossing Machines:

Embossing machines are used to create raised or recessed designs on paper surfaces, adding texture and dimension to paper decorations. These machines use pressure and heat to press metal dies or embossing folders onto paper materials, creating visually striking effects such as floral motifs, geometric patterns, and decorative borders.

- 3D Printers:

3D printers have revolutionized paper decoration production by enabling the creation of complex three-dimensional structures from paper materials. These printers use additive manufacturing technology to build up layers of paper filament, creating intricate sculptures, models, and decorations with remarkable detail and precision.

- Digital Printing Equipment:

Digital printing equipment allows for high-quality printing of designs, patterns, and graphics onto paper materials, offering endless possibilities for customization and personalization. These printers utilize advanced printing technologies such as inkjet or laser printing to produce vibrant, detailed images on paper, enhancing the visual appeal of paper decorations.