Exploring the Production Cycle of Paper Decorations

In the realm of aesthetics and ambiance, paper decorations stand as timeless elements, adding charm and character to various events and spaces. From elaborate weddings to festive celebrations, paper decorations have entrenched themselves as indispensable assets in the world of decor. However, behind their delicate allure lies a meticulous production cycle that blends craftsmanship with modern technology. In this blog, we embark on a journey through the intricate production cycle of paper decorations, shedding light on manufacturing processes, product technology, and Essential equipment.

Understanding Paper Decoration Manufacturing

At the heart of every paper decoration lies a thoughtful manufacturing process that transforms ordinary paper into intricate designs. The journey begins with the selection of high-quality paper, chosen for its texture, color, and weight, which profoundly influences the final product. This carefully curated paper undergoes a series of transformations orchestrated by skilled artisans and cutting-edge technology.

Embracing Product Technology

Product technology serves as the cornerstone of Innovation in paper decoration manufacturing. With advancements in design software and automated machinery, manufacturers can push the boundaries of creativity and efficiency. Computer-aided design (CAD) software empowers designers to craft intricate patterns and designs with precision, fueling a realm of endless possibilities.

Moreover, automated cutting and folding machines revolutionize the production process, enhancing speed and accuracy while minimizing manual labor. These machines meticulously cut and shape paper into various forms, from delicate flowers to intricate garlands, with unmatched precision. By embracing product technology, manufacturers can streamline operations, optimize resource utilization, and elevate the quality of paper decorations.

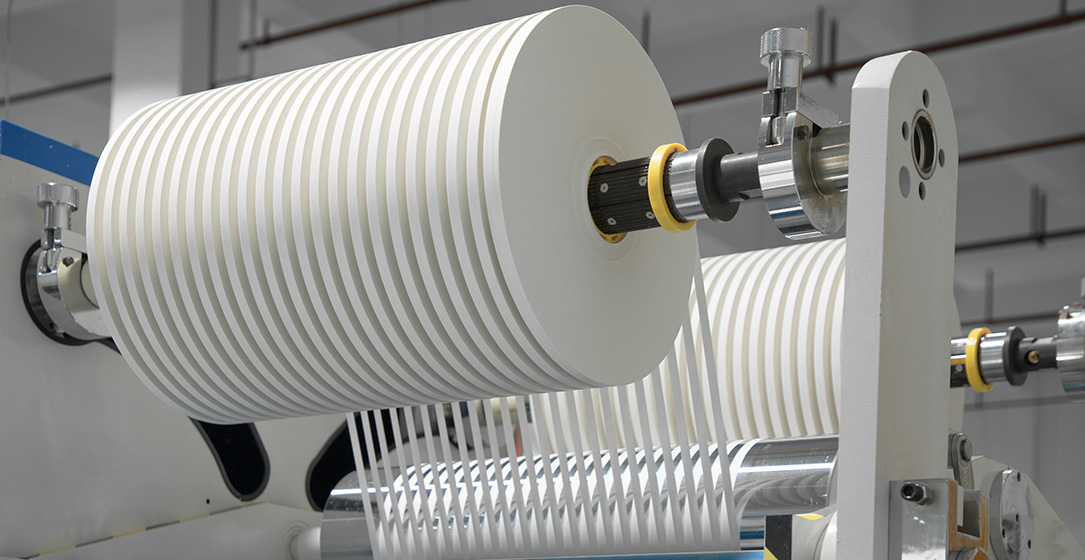

Essential Paper Decoration Equipment

A diverse array of equipment plays a pivotal role in the Production cycle of paper decorations, ensuring seamless execution at every stage. Among the essential equipment are cutting machines, which wield sharp blades or lasers to intricately shape paper into desired forms. These machines not only enhance precision but also minimize waste, contributing to sustainable manufacturing practices.

Additionally, folding machines expedite the assembly process by swiftly folding paper into intricate designs, such as origami-style ornaments and decorative fans. Printing equipment further enhances customization options, enabling manufacturers to imprint designs or logos onto paper decorations with utmost accuracy.

Navigating the Production Cycle

The production cycle of paper decorations unfolds in a series of meticulously orchestrated steps, each contributing to the creation of exquisite end products. It begins with the conceptualization of designs, where creativity intertwines with practicality to bring visions to life. Designers leverage CAD software to refine patterns, ensuring every detail meets exacting standards.

Once designs are finalized, the manufacturing process commences, with raw materials undergoing transformation into tangible forms. Cutting machines meticulously carve intricate shapes, while folding machines breathe life into flat sheets of paper, imbuing them with dimension and depth.

Printing equipment adds a personalized touch to paper decorations, allowing for custom designs and branding elements. Whether it's intricate floral patterns or corporate logos, printing technology ensures every detail is impeccably rendered.

Assembled components are meticulously crafted into cohesive designs, with artisans lending their expertise to ensure impeccable quality. Finally, paper decorations undergo rigorous inspection and packaging, preparing them for distribution to eager customers around the globe.

Challenges and Innovations

While the production cycle of paper decorations is marked by innovation and efficiency, it's not without its challenges. Manufacturers must navigate fluctuations in raw material costs, optimize production workflows, and uphold quality standards amidst evolving consumer preferences.

Furthermore, Sustainability emerges as a pressing concern, prompting manufacturers to explore eco-friendly alternatives and adopt sustainable practices. From utilizing recycled materials to minimizing waste and energy consumption, the industry is embracing sustainability as a cornerstone of responsible manufacturing.

Despite these challenges, innovation remains the driving force behind the evolution of the paper decoration industry. Whether it's experimenting with new materials, harnessing emerging technologies, or embracing sustainable practices, manufacturers continue to push boundaries and redefine what's possible.

Conclusion

In conclusion, the production cycle of paper decorations epitomizes the delicate balance between tradition and innovation. Through a harmonious blend of craftsmanship and technology, manufacturers transform ordinary paper into extraordinary works of art, adorning spaces with beauty and elegance.

As the industry continues to evolve, fueled by advancements in Product technology and a commitment to sustainability, the future of paper decorations shines bright with promise. With each meticulously crafted ornament, the essence of creativity and ingenuity unfolds, enriching lives and spaces with timeless charm.