Sustainability | Innovation

Get a Quote

or call +852 9742 1492

Home >

News >

Crafting Elegance: Mastering Production Specifications for Paper Decorations

Company News

Crafting Elegance: Mastering Production Specifications for Paper Decorations

This article explores the manufacturing process of paper decorations, emphasizing the importance of precision and technology in creating these versatile adornments. It covers the selection of high-quality materials, advancements in product technology like digital printing and die-cutting machines, the role of automation, and environmental considerations. Ultimately, it highlights the balance between innovation and sustainability in crafting elegant paper decorations.

Published by

Harborapaper at

Saturday 01, 2023

Introduction:

In the realm of interior decoration, paper decorations have long been heralded for their versatility, affordability, and eco-friendliness. From intricate origami pieces to whimsical paper garlands, these delicate creations have the power to transform any space into a whimsical wonderland. However, behind the beauty of these paper adornments lies a meticulous process of manufacturing, requiring precise production specifications and cutting-edge technology. In this blog, we delve into the world of Paper decoration manufacturing, exploring the essential elements of Product technology, equipment, and techniques that contribute to the creation of these stunning embellishments.Understanding Paper Decoration Manufacturing:

The journey of crafting paper decorations begins with the selection of suitable materials. High-quality paper is paramount, as it dictates the durability, texture, and aesthetic appeal of the final product. Manufacturers often opt for specialty papers such as cardstock, crepe paper, or tissue paper, each offering unique properties that enhance the finished decorations.Product Technology in Paper Decoration Manufacturing:

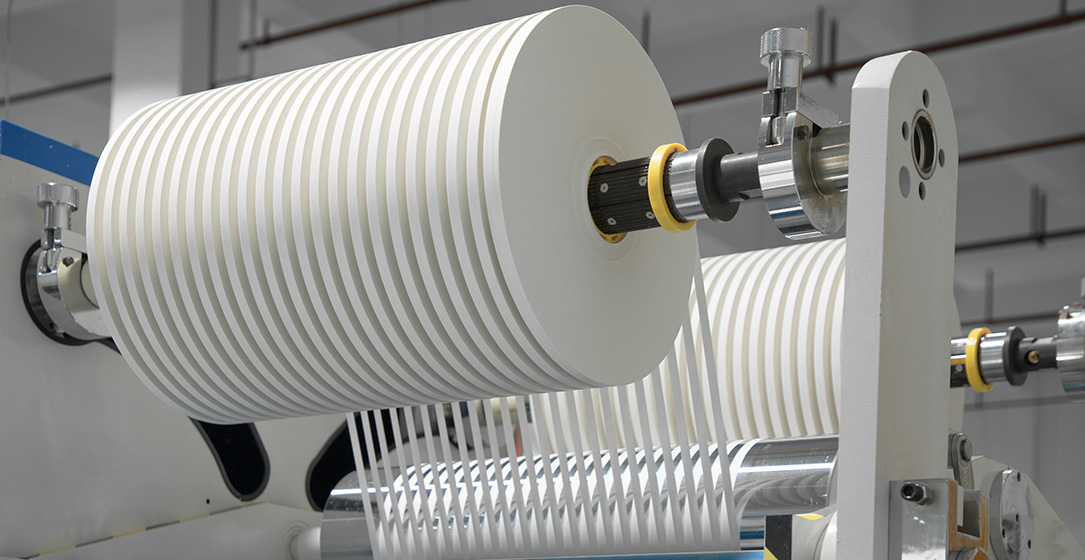

Advancements in product technology have revolutionized the production process of paper decorations, enabling manufacturers to achieve precision and efficiency like never before. One of the key technologies utilized in this sector is digital printing. Digital printing allows for intricate designs, vibrant colors, and customizable patterns to be transferred onto paper with exceptional clarity. This technology not only accelerates production but also offers endless creative possibilities, catering to diverse consumer preferences.Moreover, Die-cutting machines play a crucial role in shaping paper decorations with precision and consistency. These machines utilize custom-made dies to cut intricate shapes and designs, ensuring uniformity across each piece. Whether it's delicate snowflakes or intricate floral motifs, die-cutting machines streamline the manufacturing process, reducing waste and maximizing productivity.

Embracing Automation:

In recent years, Automation has emerged as a game-changer in the realm of paper decoration manufacturing. Automated assembly lines equipped with robotic arms and conveyor systems enable seamless production from start to finish. These automated processes not only enhance efficiency but also minimize human error, resulting in higher quality products and faster turnaround times.Furthermore, advancements in robotics have led to the development of folding and gluing machines tailored specifically for paper decorations. These machines automate the intricate process of folding and bonding paper components, eliminating the need for manual intervention and significantly increasing production capacity.

Environmental Considerations:

While technological advancements have propelled the efficiency of paper decoration manufacturing, sustainability remains a top priority for industry players. Manufacturers are increasingly adopting eco-friendly practices and materials, such as recycled paper and water-based inks, to minimize environmental impact. Additionally, efficient waste management systems ensure that leftover paper scraps are recycled or repurposed, further reducing the ecological footprint of production operations.Conclusion:

In the realm of interior decoration, paper decorations continue to captivate with their charm and versatility. Behind every intricately folded origami crane or meticulously crafted paper garland lies a sophisticated manufacturing process driven by innovation and technology. From digital printing to automated assembly lines, the production specifications for paper decorations encompass a wide array of techniques and equipment designed to achieve excellence in quality and efficiency. As the industry evolves, embracing sustainability and technological advancements will be key to shaping the future of paper decoration manufacturing, ensuring a harmonious balance between beauty and Environmental responsibility.

Get The Personalized Solution

A complete solution for your paper product manufacturing is available now!

Yours is the most important voice. If you have any questions or comments for us, please use the form below to send them to us. Thanks!