Introduction:

In the realm of interior decoration, paper adornments have become increasingly popular for their versatility, charm, and eco-friendliness. From intricately folded origami to whimsical paper garlands, these decorations add a touch of whimsy to any space. However, behind the scenes of Paper decoration manufacturing lies a critical process that ensures the integrity and quality of each piece: production quality inspection. In this blog, we will explore the importance of production quality inspection in paper decoration manufacturing, examining its role in upholding standards of excellence, integrating product technology, and optimizing paper decoration equipment.

The Importance of Production Quality Inspection:

Production quality inspection is a crucial step in the manufacturing process of paper decorations, ensuring that each piece meets predetermined standards of quality, craftsmanship, and aesthetic appeal. This process involves systematic examination of every aspect of the decoration, including visual appearance, structural integrity, dimensional accuracy, and adherence to design specifications.

By conducting production quality inspection, manufacturers can identify defects, deviations, and inconsistencies early in the production process, allowing for timely corrective action and the delivery of high-quality paper decorations to customers. Additionally, production quality inspection serves as a means of maintaining consistency, reliability, and customer satisfaction in paper decoration manufacturing.

Visual Inspection and Aesthetic Appeal:

Visual inspection plays a pivotal role in production quality inspection, allowing inspectors to assess the overall appearance, color accuracy, and print quality of paper decorations. This involves examining the surface finish, texture, and clarity of printed designs to ensure that they meet the desired aesthetic standards.

Advanced product technology, such as digital imaging systems and colorimeters, enhances the accuracy and efficiency of visual inspection, enabling inspectors to detect subtle variations and defects that may not be visible to the naked eye. By leveraging digital tools and automation, manufacturers can achieve higher levels of precision and consistency in assessing the visual quality of paper decorations.

Structural Integrity and Durability:

In addition to visual inspection, production quality inspection involves evaluating the structural integrity and durability of paper decorations. This includes assessing the strength, stability, and assembly of each piece to ensure that it withstands handling and display without damage or deformation.

Specialized equipment, such as magnifying lamps and calipers, facilitates dimensional inspection, allowing inspectors to verify that each decoration meets precise specifications in terms of size, shape, and proportion. Moreover, automated inspection systems equipped with sensors and cameras enable manufacturers to streamline inspection processes and minimize human error.

Integration of Product Technology:

The integration of product technology has transformed production quality inspection in paper decoration manufacturing, enhancing efficiency, accuracy, and consistency. Digital printing technology, for example, enables manufacturers to reproduce intricate designs with stunning clarity and detail, while automated die-cutting machines ensure precise cutting and shaping of paper components.

Moreover, advancements in machine vision technology enable automated inspection of dimensional accuracy, color consistency, and print quality, reducing the need for manual inspection and improving throughput. By integrating product technology into production quality inspection, manufacturers can achieve higher levels of precision, consistency, and efficiency in assessing the quality of paper decorations.

Optimization of Paper Decoration Equipment:

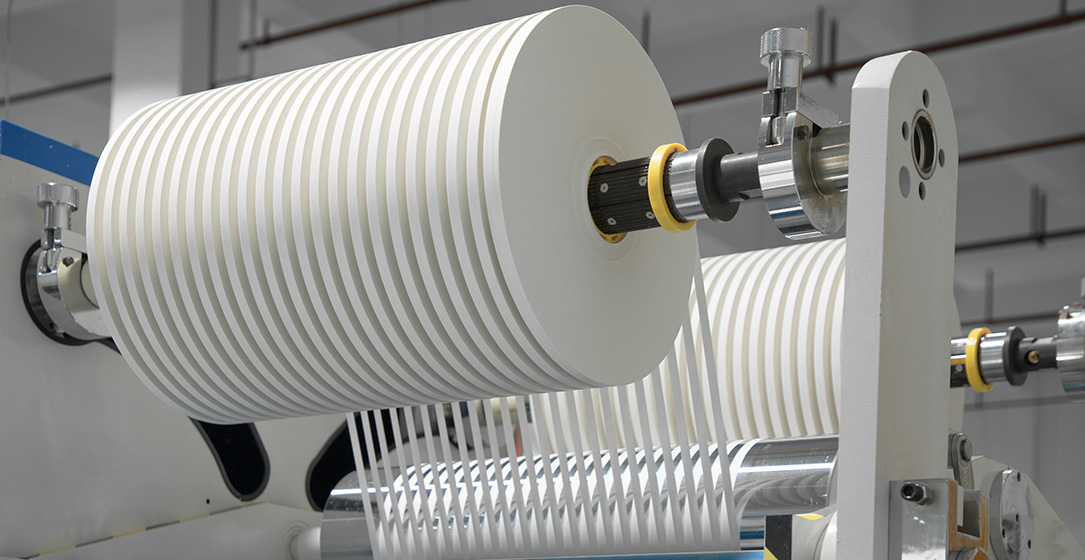

Central to production quality inspection is the optimization of Paper decoration equipment to facilitate accurate and efficient inspection processes. Specialized equipment, such as folding and gluing machines, play a crucial role in assessing the structural integrity and assembly of paper decorations.

Regular maintenance, calibration, and upgrades are essential to ensuring that equipment operates at peak performance and efficiency, minimizing downtime and maximizing productivity. By investing in state-of-the-art inspection equipment and providing comprehensive training to inspectors, manufacturers can optimize production quality inspection and ensure the delivery of flawless paper decorations to customers.

Conclusion:

In conclusion, production quality inspection is a critical aspect of paper decoration manufacturing, ensuring that each piece meets predeterm ined standards of quality, craftsmanship, and aesthetic appeal. By conducting Visual inspection, evaluating structural integrity, integrating product technology, and optimizing equipment, manufacturers can uphold standards of excellence and deliver High-quality paper decorations to customers.

As the industry continues to evolve, Production quality inspection will remain a cornerstone of excellence, driving continuous improvement, innovation, and customer satisfaction in paper decoration manufacturing. By embracing advanced product technology, optimizing equipment, and implementing rigorous inspection protocols, manufacturers can maintain a competitive edge in the dynamic world of interior decoration.